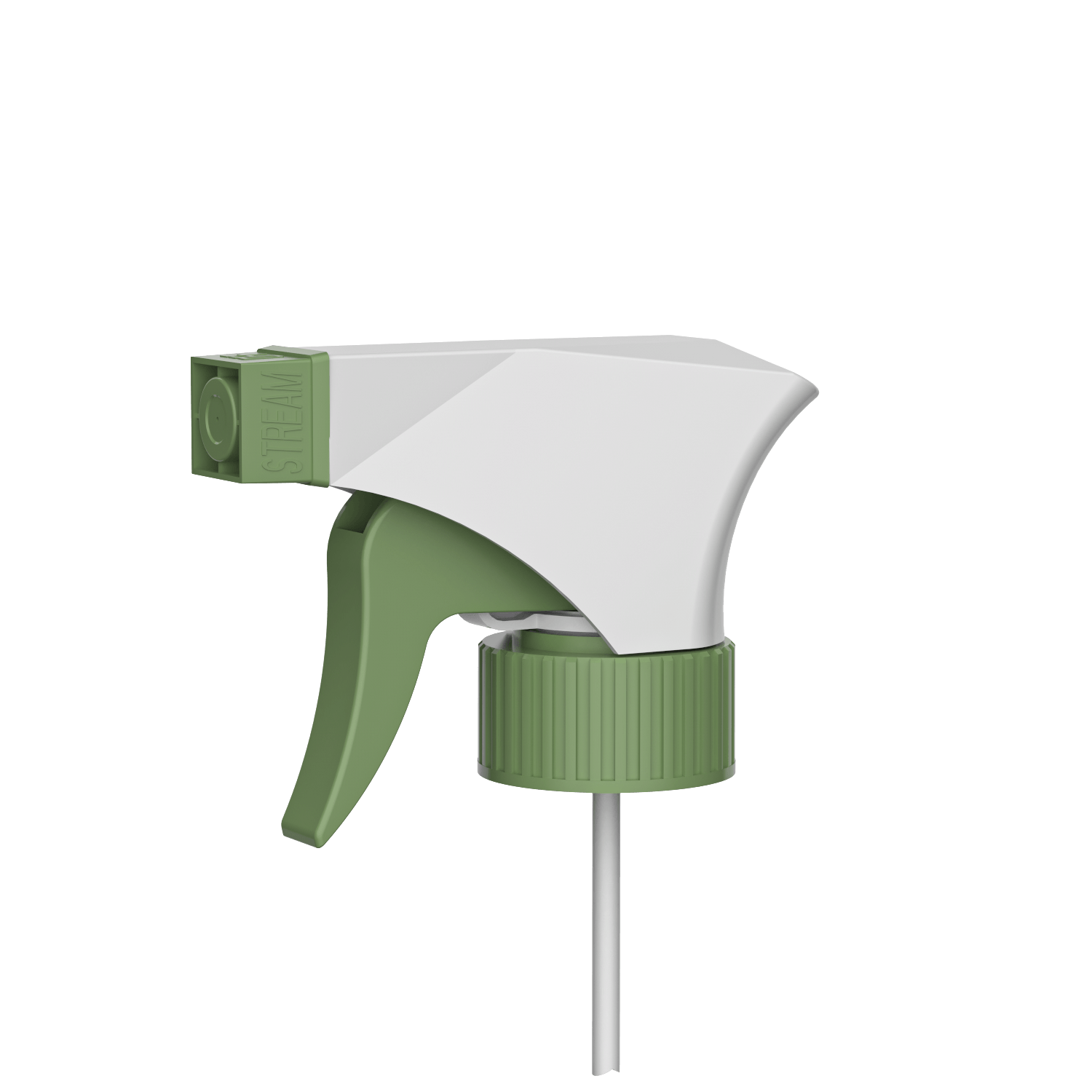

2. The advantage of HD-102A and HD-102B plastic trigger sprayer is the use of plastic spring, and in the design of the spring on the outside of the trigger sprayer body, no contact with liquid. So it will not occur like steel wire spring liquid contact corrosion reaction.

3. The spring of ordinary stainless steel spring trigger sprayer is usually in the piston cylinder of the trigger sprayer, directly in contact with the liquid. So there are certain requirements for the PH value of the liquid. If the liquid PH<7, while stainless steel springs are exposed to PH<7 for a long time, corrosion may occur. Lead to stainless steel surface oxidation and rust. The surface of the spring oxidation layer off, so that liquid will metamorphic. Corrosion resistance of stainless steel springs is: 316>301>201 Materials.

Yuyao Hongda Sprayer Co., Ltd. has 26 years of research and development ability and production experience. We can be customized according to the different requirements of customers, and quickly provide solutions.

.png?imageView2/2/format/jp2)

English

English Español

Español русский

русский Français

Français italiano

italiano Deutsch

Deutsch